How to choose the right combine harvester machine for your farm

What is a combine harvester?

A combine harvester is a powerful and versatile agricultural machine designed to efficiently harvest a variety of grain crops. It combines three key operations — reaping, threshing, and winnowing — into one process, making it a critical piece of equipment for large-scale grain production.

- Reaping: Cutting the crops at the base and gathering them.

- Threshing: Separating the edible part (grain) from the rest of the crop.

- Winnowing: Removing chaff (non-grain material) from the harvested grain.

Combine harvesters are typically used for harvesting crops like wheat, rice, corn, barley, soybeans, oats, and even some pulses. These machines save time and labor by performing multiple tasks simultaneously, allowing farmers to harvest large areas in a short amount of time.

How to choose the right combine harvester for your farm:

A combine harvester is one of the most important machines in modern farming, particularly in India, where large areas of land are dedicated to cereal and grain crops like wheat, rice, maize, soybeans, and pulses. Choosing the right combine harvester for an Indian farm involves considering various factors such as farm size, crop type, terrain, budget, and operational needs. The right combine harvester can significantly increase efficiency, reduce labor costs, and enhance overall productivity.

Here's a guide to help you choose the perfect combine harvester for your farm in India:

1. Assess your farm size and type of crops

The first step in choosing a combine harvester is understanding your farm's size and the type of crops you grow. Indian farms vary greatly in size, from smallholdings to large commercial farms. The type of crop also plays a crucial role in selecting the right machine.

- Small Farms (1-5 hectares): For small-sized farms, compact or mini combine harvesters are ideal. These are designed to handle crops like rice and wheat with a relatively low cost of operation.

- Medium Farms (5-20 hectares): A mid-sized combine harvester will work best for medium-sized farms. These machines can harvest multiple crops, including wheat, rice, and maize, and are more efficient in terms of fuel consumption and productivity.

- Large Farms (20+ hectares): For larger farms, high capacity combine harvesters with powerful engines, large grain tanks, and multi-crop functionality are ideal. These machines can cover extensive areas quickly, reducing downtime.

2. Engine power and capacity

The engine power of a combine harvester dictates how efficiently it can harvest crops, especially on larger farms or in tough soil conditions. The power of the engine is measured in horsepower (HP) and usually ranges from 40 HP for small models to over 300 HP for large, high-capacity machines.

- For Small Farms: A 40-60 HP combine harvester is sufficient. It can handle small fields and crops like rice, wheat, and pulses.

- For Medium-Sized Farms: Choose a combine with 60-120 HP. These machines provide enough power for larger fields while maintaining fuel efficiency.

- For Large Farms: A high-powered combine harvester with 120-250 HP will be required for vast farm areas, ensuring quick and efficient harvesting without constant stoppages.

3. Type of crops

Different combines are designed for specific crops. The choice of harvester depends on whether you are harvesting cereal crops (like wheat, barley, and rice) or row crops (like maize and soybeans).

- Wheat, barley, and rice: These crops require combine harvesters with specialized cutting headers, straw walkers, and threshing units.

- Maize, sorghum, and soybeans: For row crops, you need a combine with a corn header that can easily pick up and separate the crops from the soil.

- Multi-crop harvesters: For farms that grow a mix of crops (like wheat, paddy, and soybeans), a multi-crop combine harvester is the best option. These machines are designed to work efficiently across different crop types, offering adjustable settings for threshing and harvesting.

4. Grain tank capacity

The grain tank is an important factor to consider, as it dictates how much grain the harvester can hold before it needs to be emptied. A larger grain tank allows for longer hours of continuous operation.

- Small tank (1000-2000 liters): Suitable for small farms where the harvester is emptied frequently and unloading stations are available.

- Medium tank (2000-4000 liters): Ideal for medium-sized farms with moderate acreage.

- Large tank (4000+ liters): Best for large farms that require fewer stops for unloading, allowing for maximum efficiency during harvesting.

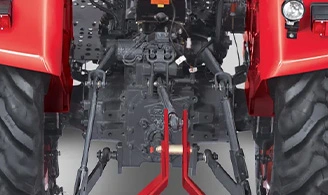

5. Hydraulic lifting capacity

The hydraulic system of a combine harvester controls the movement of the header and auger. The lifting capacity determines how high the header can lift crops and how effectively the machine can handle dense crop material.

- Higher capacity: For fields with tall crops like maize or dense paddy fields, a higher hydraulic lifting capacity is crucial to prevent crop loss and ensure proper harvesting.

- Adjustable settings: Some models allow for adjustable hydraulic settings, enabling the machine to be adapted to different crop heights and field conditions.

6. Technology and automation

Modern combine harvesters are equipped with various technological features to improve efficiency, reduce labor, and increase precision. Some of these features are particularly useful in Indian farming conditions:

- GPS guidance systems: Ensure precise operation, reduce overlapping of work, and help with fuel efficiency.

- Yield mapping: Advanced models come with yield monitoring and mapping systems, helping farmers track crop yield across their fields.

- Automatic settings: Many machines now feature automatic adjustment for threshing, cleaning, and separation based on crop type, which reduces the need for manual intervention.

- Auto-adjusting headers: Helps adapt to changing crop heights and different harvesting conditions.

7. Terrain and field conditions

Indian farms often have varying terrain, such as uneven ground, wet fields, and narrow rows, which can impact the performance of the combine harvester. Consider these factors:

- 4WD (four-wheel drive): For uneven or hilly terrains, a 4WD combine harvester will provide better traction and stability.

- Compact design: For farms with narrow pathways, compact or narrow body combines are better suited as they can easily navigate tight spaces.

- Track system: In fields with wet or soft soil, combine harvesters with tracked systems (instead of traditional tires) distribute the machine's weight better, reducing soil compaction and enhancing mobility.

8. Maintenance and service support

A combine harvester is a major investment, so it's essential to choose a machine from a reliable brand that offers good service support and maintenance options. Many manufacturers offer extended warranties, spare parts availability, and quick servicing options.

- Local dealer network: Choose brands with a strong presence in your region, so service and repairs are easily accessible.

- Ease of maintenance: Look for combines with easily accessible parts for routine maintenance and repairs.

9. Budget and financing

The price of a combine harvester can range from a few lakhs to several crores, depending on the size, features, and brand. In India, several government schemes and subsidies are available to assist farmers with purchasing agricultural machinery, including combine harvesters. It’s important to:

- Set a Budget: Assess your farm’s requirements and determine how much you’re willing to invest.

- Explore Financing Options: Many banks and financial institutions offer loan schemes for purchasing farm equipment.

- Government Subsidies: Investigate available subsidies under schemes like the Pradhan Mantri Krishi Sinchayee Yojana (PMKSY) or state-specific schemes that support the purchase of combine harvesters.

10. Brand reputation and after-sales support

Choosing a reputable brand with strong after-sales support and service is essential for ensuring the long-term reliability of your combine harvester.

Conclusion: Choosing the right combine harvester

Selecting the right combine harvester depends on several key factors, including your farm size, the types of crops you grow, and your specific harvesting needs. It's important to balance features like power, header compatibility, grain tank capacity, and technology with your budget. Investing in a combine harvester that suits your operational needs can greatly improve efficiency, reduce labor costs, and increase the profitability of your farming operation.

Make sure to do thorough research, test different models, and consult with experts to find the best combine harvester for your farm’s unique requirements.